Lumber Prices

The cost of lumber, when looking at the NASDAQ for the past 6 months on a chart shown below, was at an all time high on May 21, 2021. Working in the business of wood, it is interesting to speak with different suppliers of doors, architects, general contractors, developers and such on the topic of how exactly is this affecting the construction industry? There are so many challenges, surrounding this major issue in the industry. Many have expressed that of course budget is being affected, but also timeline for the projects. Some items are at such a shortage, that they are given unappealing lead times, for things that you would NEVER have to have a lead time on in years past. This article will dig into the different ways projects are being affected by this lumber situation in the US (in terms of doors) and some alternatives to solving these issues for the projects to remain on course.

This Lumber Report, shows a visual representation of the last 6 months in the cost of lumber as a whole over that time. You can see that very recently, on May 21, 2021, lumber hit an all time high. The trend is going down, but still astronomically higher than the cost of lumber over the past few years. This elevated cost has trickled down into every area of building and construction, but this article will concentrate on how to help your project stay on track with interior closet doors.

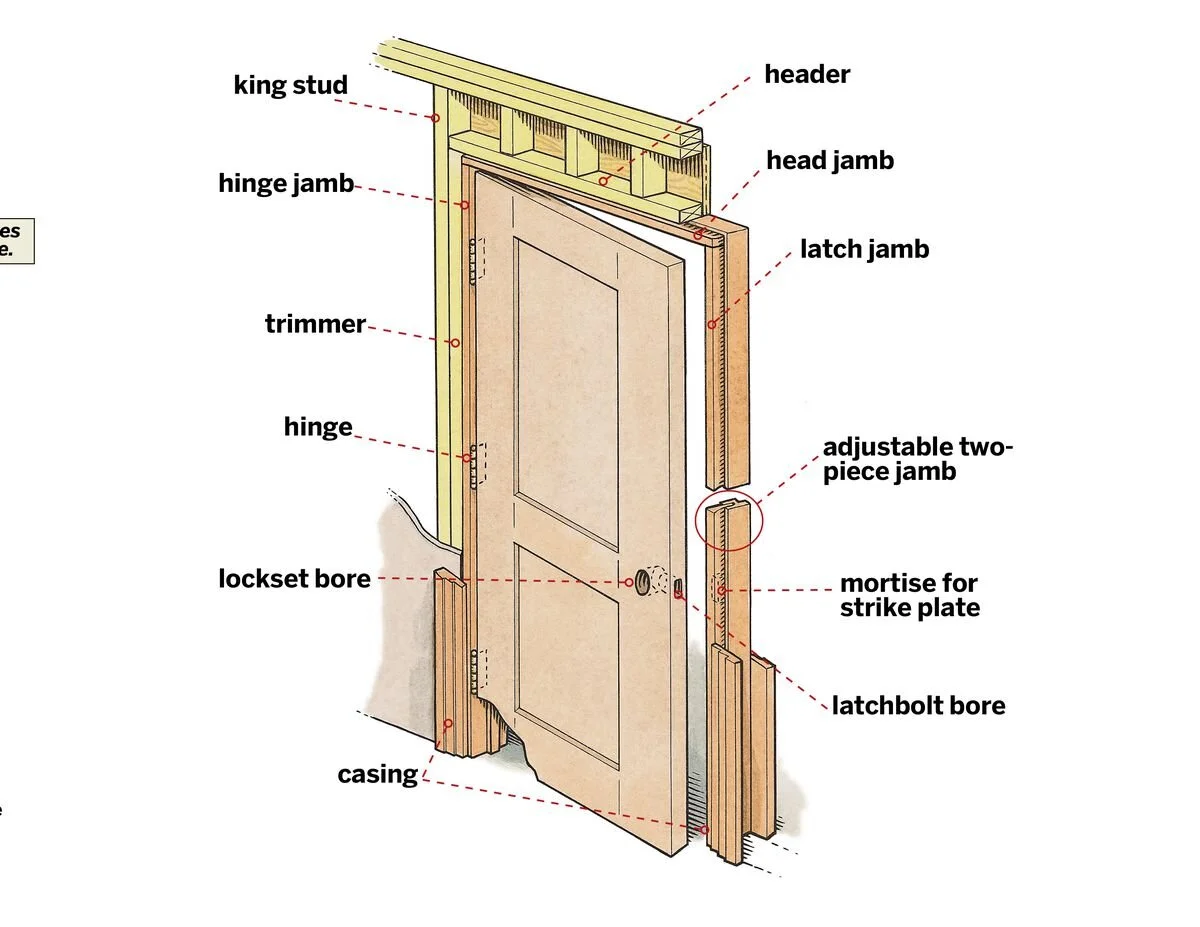

Important fact, prehung closet doors all require casing in order to set the door correctly. This diagram below shows inside the wall of a typical interior closet door. When specifying a type of door with a lock set, like a prehung door, this wooden casing is mandatory on the inside of the door in order for the door to be installed. This casing, is also an extremely hot commodity right now. Pine and Poplar, the most used type of wood for this casing is unfortunately up in price by 50% in many suppliers, if they can even get their hands on it. I have spoken with a few suppliers that mentioned to me the company they buy their casing from, can’t give them a lead time on prehung casing because the market is so unstable.

How do I avoid this casing?

The answer, is to avoid large amounts of prehungs throughout your units if possible. There are many other options out there for closet doors, so architects-developers-project managers should be getting creative in terms of avoiding this unnecessary increase in cost and lead time for the project. Other types of closet doors include: bifolds, pivots, bipass, and barn. Clearly, the pocket door is filled with casing as well and should be avoided currently.

Using any of the 4 for a closet door currently, is a good idea however, this needs to be investigated further as well. Some of these types of products can be made from particleboard. According to plyreporter.com, Imported particleboard has seen a price increase of about 20%. The cost of wood, resin and a shortage in India, China, Malaysia and Thailand as well as the increasing ocean freight charges are all responsible for this import particleboard price hike.

How do I avoid imported particleboard costs?

The best way to avoid imported particleboard costs is to go with a manufacturer that uses domestic particleboard currently. It is extremely hard to figure out what manufacturer’s use for their product lines. Some manufacturer’s of doors claim to be fully made in the USA, but this can also just be that the door was manufactured in the USA once the material came in from overseas. At Landquist & Son, we can safely say that we all of our closet doors are fully manufactured, material and all, in the USA. Our costs have not been drastically driven up due to COVID-19.